Design Engineering‘s next generation method of chilling the temperature of fuel before entering the intake stream is now available – the CryO2 Fuel Chiller System!

The new CryO2 Fuel Chiller System uses the cryogenic properties of liquid CO2 to charge a series of internal cryogenic chambers surrounding the center “fuel” chamber. As the fuel passes through the center chamber, the cryogenic-charge chambers super cool the fuel by maximizing the thermal transfer process removing heat four times more effectively than any other system available today.

As the temperature of fuel is reduced it increases in density. The denser fuel results in better and more efficient burning of the fuel – consequently generating more power and greater fuel efficiency.

Heat created by high pressure fuel pumps, high under hood temperatures, heat from header and exhaust manifolds, etc., all combine to raise the temperature of fuel and creates a potentially lean condiiton or “vapor lock” that can damage the engine.

The CryO2 Fuel Chiller System can be used along with your existing CryO2 system, or a nitrous oxide system, to lower fuel temperatures and improve HP and efficiency and reduce the chances of engine damage.

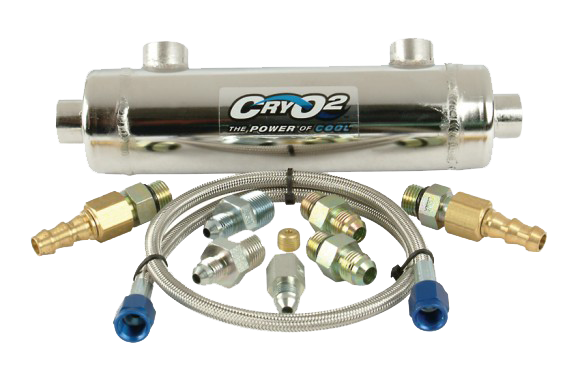

Each CryO2 Fuel Chiller System comes complete with two (2) -4AN and -6AN fittings as well as two (2) 3/8″ barb fittings and mounting brackets and hardware. Also in the kit is a 2-foot length stainless steel braided hose for use with -4AN fittings to allow a connection to other components such as a CryO2 Air Intake or CryO2 Intercooler Sprayer.

Features & Benefits

•Removes heat from fuel greatly improving fuel density

•Super cooling efficient design maximizes thermal transfer process

•Reduce chances of detonation

•Cooler fuel reduces chance of lean condition and vapor lock

•Utilizes DEI’s CryO2 system or existing nitrous system

•Lowers air & fuel intake charge temps improving horsepower and efficiency

•Easy install

For more information call “1-800-997-TINT”